- Courses

- ItemPath Integration Guide

- Understanding Power Pick

Understanding Power Pick

Power Pick — formally Kardex Power Pick Systems — software by Kardex Remstar, works as a warehouse management system (WMS) solution, built to optimize and streamline warehouse processes using associated machinery. Workers will interact with Kardex storage units through Power Pick to fulfill requests to retrieve items from the system. ItemPath works as an application programming interface (API), middleware, and analytics engine between Power Pick and your enterprise resource planning system.

This course page will discuss some of the Power Pick requirements before you can set up an integration using ItemPath, and familiarize you with some basic Power Pick terminology.

Connection requirements

When setting up ItemPath for managing integrations, the following information is required from Power Pick:

- Username and password (should be for a database owner user)

- Database name

- Dedicated IP address and port number (default 1433)

If you are using ItemPath Cloud: The dedicated IP address should be a public IP accessible outside of internal networks. - If using an MSSQL database, the Power Pick SQL Server will need to be able to accept remote connections via IP (see SQL server documentation)

The Power Pick CEU (Cross Enterprise Unit) Web Services Interface module is also required for using our integration services. You should note the following details for setting up the module for communication with ItemPath:

- Username & password of a Power Pick user, ideally with Admin-level command rights

- Dedicated IP and port number (default 1353) for the machine running the Power Pick Cross Enterprise Unit Service (typically also running the rule engine)

ItemPath Cloud: The dedicated IP address should be a public IP accessible outside of internal networks - Web Client station in Power Pick (see documentation)

Some Basics

You may want to familiarize yourself with some key terminology to help explain how ItemPath and Power Pick categorize Order fulfillment data:

Term | Definition |

| Order | A request to complete a task within Power Pick. These can be to pick, put, or otherwise move materials, or count the materials at a location. |

| Order Line | A specific task within an order for a unique material and quantity. Orders can be composed of multiple Order Lines. |

| Transaction | The record of various steps that are completed throughout the process of order fulfillment. |

| Requested Quantity | The total amount of material requested by the external system for a specific order line. |

| Confirmed Quantity | The actual amount of material the worker successfully picked, put, or counted during a transaction. |

| Deviated Quantity | The difference between the Requested Quantity and the Confirmed Quantity (e.g., if 10 were requested but only 8 were found, the deviation is 2). |

| Payload | The data sent by ItemPath to the external system confirming the results of the transactions. |

| Consolidation | The process of grouping multiple transaction records into a single payload based on your "Consolidate Transactions" settings. |

| Material | The goods that are stored inside a Kardex storage unit. |

So, an order can include an order line to pick a material from a bin. When the picker in the warehouse completes the order, they conduct a transaction (interacting with Power Pick and/or the storage unit) to fulfill the requirements of an order line.

One order line, multiple transactions

It's important to note that one order line can result in multiple transactions. For example, a pick may need to be split across multiple bins (due to inventory levels), or a material shortage may prevent an order line from being fulfilled completely.

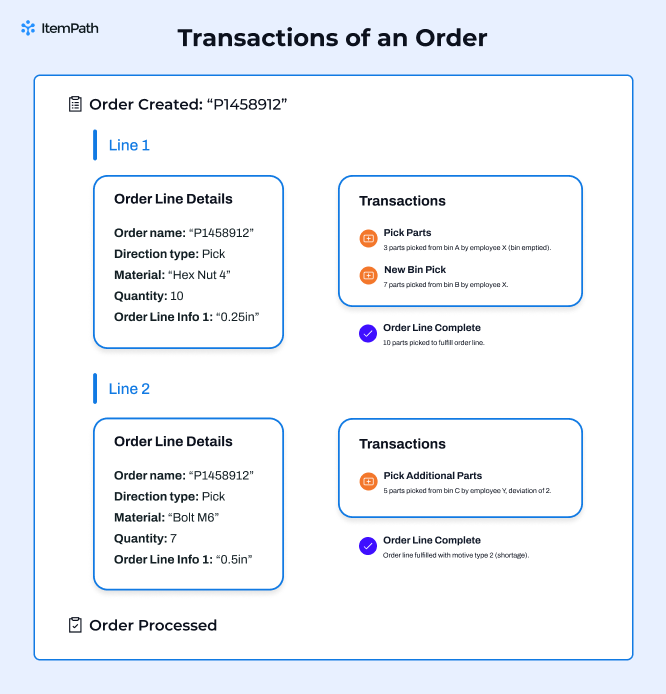

Let's go through an example with two separate order lines:

Order Line 1: Hex Nut 4 (Requested Quantity: 10)

To fulfill this line, the worker must visit two different locations because the first bin does not have enough stock.

- Transaction 1: Employee X picks 3 parts from Bin A. This empties the bin, and the order line status updates to "In Process".

- Transaction 2: Employee X picks the remaining 7 parts from Bin B.

- Result: The order line status is now "Complete". There is no deviated quantity because the full requested quantity was found and confirmed.

Order Line 2: Bolt M6 (Requested Quantity: 7)

This line demonstrates a scenario where the requested quantity cannot be met.

- Transaction 1: Employee Y picks 5 parts from Bin C. They find that the bin is now empty and no lother locations contain this material.

- Result: The order line status is now "Complete" with a confirmed quantity of 5 and a deviated quantity of 2.

Consolidate Transactions

With Data Push, transactions can be consolidated so only one confirmation is sent per order line, rather than sending a separate notification for every single physical action.

If Consolidate Transactions is set to:

- Disabled: A confirmation is sent for every individual transaction.

- In our example: Three separate payloads are sent (Transaction 1 for Hex Nuts, Transaction 2 for Hex Nuts, and the pick for Bolts).

- Consolidate Lines: A confirmation is sent for every completed line.

- In our example: Two payloads are sent. The two transactions for the Hex Nut 4 line are bundled together into one message.

- Consolidate Orders: A confirmation is sent only when the entire order is complete.

- In our example: Only one single payload is sent once all actions for Order #P1458912 (both the Hex Nuts and the Bolts) are finished.

Stored materials only

When creating a Power Pick order, a “pick” order takes materials out of a storage unit, and a “put” order puts materials in. If the order line includes a material Power Pick doesn’t recognize, an error will be returned. That means orders can’t include parts not in Power Pick. Filtering for only materials in a bin called “KARDEX” works for most integrations. Additionally, Data Pull can be used to make new material records so that put orders can be created to place new materials into your storage units.

Because Power Pick storage units are designed to determine optimal locations based on material storage rules, zones, and other logic, ERPs usually treat it like a “black box” and don’t need to set or record specific locations beyond warehouse and storage unit or station.

Two inventories

Between inventory records in your ERP software and Power Pick, Power Pick’s will be more reliable because of user confirmation. Use the API to get material quantities or ItemPath’s Variance app to check for discrepancies on a regular basis.

Plus, ItemPath can report on deviated quantities and send a notification when shortages occur. With ItemPath’s Order Builder app, ItemPath can even automatically generate a “count” order to count the location or material that was marked empty or missing. Inventory accuracy goes way up with these tools!

Other requirements

Before building integrations with ItemPath, you will need to have both ItemPath and Power Pick configured. The main feature that is required for your Power Pick system to work with our integration services (for creating orders) is the Power Pick CEU Web Services Interface module.

Other modules are available that ItemPath can work with, including:

- Database Configurator: Enables Dynamic Fields in Power Pick.

- Jobs: Requires the ItemPath "Jobs" app for compatibility.